Your One-Stop Shop for Engineering, Electromechanical & Construction Tools

Your One-Stop Shop for Engineering, Electromechanical & Construction Tools

Welding is a precision job, and any slight error can affect the integrity of a complete structure. Welders use welding gauges, special equipment used to measure and analyze the welds to ensure that they are in line with the industry standards. No matter the welder type, professional or not, you have to know these tools are essential in creating good welds with few mistakes.

There are different types of welding gauges each of which is designed to measure certain things. Others are concerned with the seam accuracy, but the sophisticated digital gauges can give accurate readings in seconds. Welders who know how to use these gauges not only get high quality welds but also reduce wastage of materials and mistakes.

This guide will discuss the types of welding gauges, properties, and its application in the welding industry and the role of the welding gauge in improving precision, efficiency, and safety during welding.

A welding gauge is a type of tool that is used to test different variables of welding like alignment, size, and precision. It is mainly used to make sure that welds meet specifications as required by employers and industry standards.

Welding gauges identify faults that may affect structural integrity to avoid the possible safety risk and expensive rework. They find extensive application in shipbuilding, construction, manufacturing, and aerospace (where small errors can result in large effects).

Welding gauges are either manual or sophisticated digital. Manual gauges are very convenient in routine work, whereas digital gauges are much more precise and quick to read, and they are best used in high-accuracy projects.

These features ensure welders can work efficiently, maintain quality, and avoid errors during critical welding operations.

Welding gauges are more than just measuring tools—they ensure structural strength, efficiency, and safety. Key benefits include:

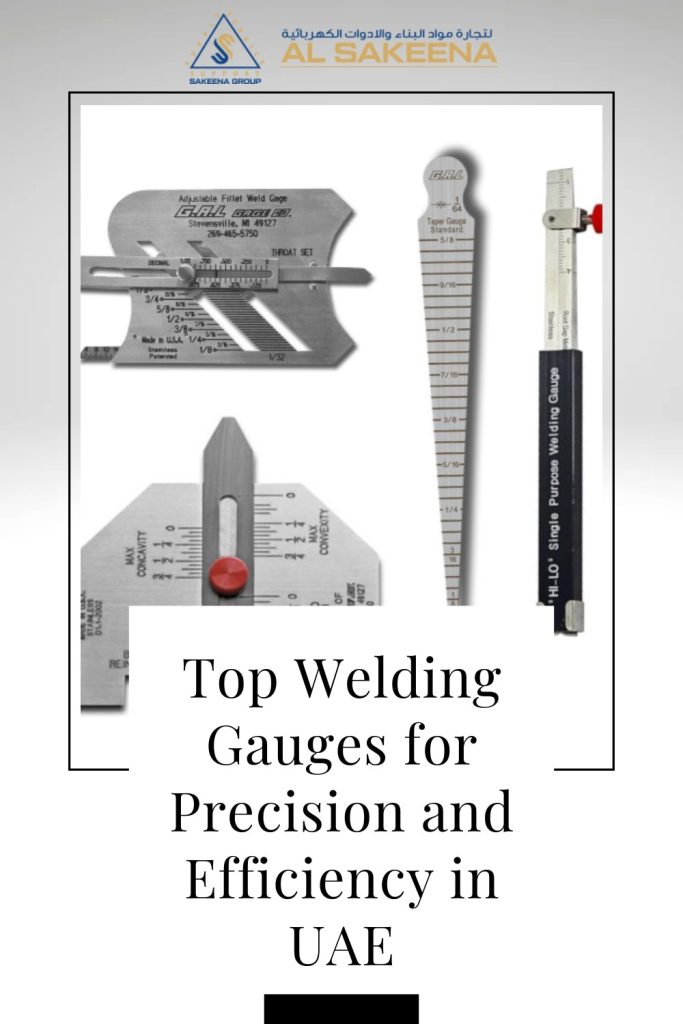

Welding gauges vary in design and function. Here are the most commonly used types:

A fillet weld gauge measures the size of fillet welds, commonly used in structural welding. It ensures that the weld’s throat thickness and leg length meet specifications. To use, place the gauge against the weld and compare readings with the required dimensions, adjusting the weld as necessary.

Adjustable fillet weld gauges offer flexibility for measuring fillet welds of varying sizes. They are ideal for dynamic projects where weld dimensions change frequently, providing both speed and precision.

These digital or semi-automatic gauges simplify measurement by automatically calculating weld size. They reduce human error and are frequently used in high-volume industrial applications.

These gauges are simple to use as they are designed to give simple measurements, which is why they are cheap and can be used during entry-level or simple welding work. Their emphasis is on the non-featured critical dimensions.

The Hi-lo gauges are used to measure the difference in the weld height to provide uniformity and consistency along the seams. They are mostly applied in structural and pipeline welding.

Pipe pit gauges are special devices that help check the welds on the cylindrical surfaces. They are critical in such industries as ship building and oil pipelines where curved welds prevail.

Angled welds are measured with taper gauges to assist welders in keeping the bevels and angles correct. This is essential when it comes to joints that need a high degree of accuracy in alignment and load-sharing.

V-wac gauges measure the internal geometry of welds, which have to be properly penetrated and fused. Applications usually include aerospace and high-precision mechanical work.

Dirt and debris can affect readings. Always clean the weld surface thoroughly before measuring.

Different gauges serve specific purposes. Using the incorrect type results in inaccurate measurements. Learn the differences and consult supervisors if unsure.

Improper placement can cause misalignment and weaker welds. Ensure the gauge is flat and properly aligned with the weld.

Digital gauges require regular calibration to maintain precision. Manual gauges also need inspection for wear and tear.

Welding gauges are indispensable in multiple sectors:

The proper welding gauge makes welders and manufacturers in UAE precise, efficient and safe. 7pc fillet weld set cat, adjustable fillet weld gage cat, automatic weld size weld gage cat, economy single purpose hi-lo welding gage cat, hi-lo welding gage cat, pipe pit gage cat, taper gage cat #sub 28a, v-wac single weld gage cat are some of the tools needed in order to come up with high quality and defect-free welds.

Quality gauges investment enhances workflow, material wastage, and industry standards. Welding gauges are essential in the shipbuilding sector, construction sector, or oil and gas.

Al Sakeena Building Materials and Electricals Trading are the best suppliers of reliable and high-quality welding tools and gauges in the UAE because the products meet the needs of all welders.