Your One-Stop Shop for Engineering, Electromechanical & Construction Tools

Your One-Stop Shop for Engineering, Electromechanical & Construction Tools

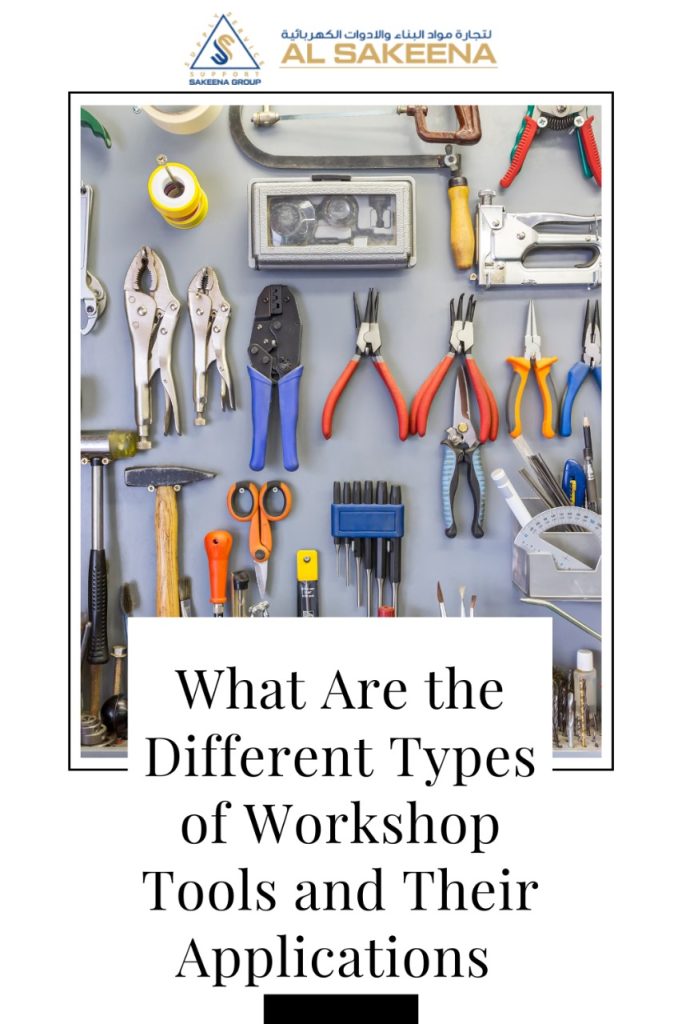

In any workshop, whether it’s for woodworking, metalworking, or general DIY projects, having the right tools is essential for completing tasks efficiently and accurately. Workshop tools come in many varieties, each designed for a specific purpose. Understanding the different types of workshop tools and their applications is crucial for ensuring that your work is precise, safe, and high-quality.

In this guide, we’ll explore the most commonly used workshop tools, their purposes, and how they fit into the overall workflow. From precision and measuring tools to electrical accessories, this blog will help you choose the right tool for your project needs.

Any successful project begins with accurate measurements. Precision and measuring tools are indispensable in ensuring that every cut, join, or fit is exact. These tools help maintain uniformity and precision, which is vital for both safety and quality.

These tools are primarily used in woodworking, metalworking, and construction projects to guarantee that all measurements are accurate before proceeding with cutting, shaping, or joining.

Cutting tools are among the most essential in any workshop. These tools help to shape materials, whether it’s wood, metal, or plastic, into the required form. The versatility and variety of cutting tools allow craftsmen and technicians to perform tasks ranging from simple cuts to more complex shaping and carving.

Using the right cutting tools is vital for ensuring that cuts are clean, accurate, and safe, whether you’re working on customized furniture, metal frames, or plastic models.

Welding plays a crucial role in metalworking, and welding gages are essential tools for ensuring that your welds are accurate and meet industry standards. These gauges are used to measure the size, quality, and penetration of the weld, making sure that the final joint is strong and reliable.

Welding gages are an invaluable asset when working with metal fabrication, ensuring that your metalwork projects are not only strong but also conform to safety regulations.

When it comes to workshop materials that offer exceptional durability and resistance, nylon & Teflon components are widely used. These materials are perfect for various applications where wear resistance, low friction, and heat resistance are required.

These materials are especially useful in automotive, manufacturing, and chemical processing industries, where the durability and non-reactive nature of nylon and Teflon are critical.

Non-ferrous tools are designed to work with metals that do not contain iron, such as aluminum, copper, and brass. These materials are typically softer and more prone to damage from tools made for ferrous metals. Non-ferrous tools are carefully designed to prevent scratching or damaging these metals during fabrication or assembly.

These tools are essential for working in metalworking, automotive repairs, and electronics manufacturing, where the use of non-ferrous metals is prevalent.

Whether you’re working on a DIY electrical project, repairing an appliance, or setting up a large-scale industrial system, electrical accessories are a must. These tools ensure that your electrical systems are safely and efficiently powered, with proper wiring, connections, and protection.

These accessories are indispensable when working with electrical installations, circuit repairs, or wiring setups, making them critical tools for both home improvement projects and industrial applications.

Each of the tools discussed in this blog plays an essential role in helping professionals and hobbyists alike achieve high-quality, safe, and efficient results. From precision and measuring tools to cutting tools and welding gages, understanding which tool is best suited to your specific needs is crucial for project success.

Remember that the key to an effective workshop lies in having the right tools for the job. Whether you’re crafting intricate models, fabricating custom metalwork, or working with electrical systems, knowing which tools to use and when to use them will elevate your projects.

For those looking to equip their workshop with top-quality tools, Al Sakeena Building Materials & Electricals Trading is a reliable supplier for all your workshop tool needs. From durable nylon & Teflon components to non-ferrous tools for metalworking, you can trust them to provide the best materials and accessories for your projects.